Energy wood burning heat and power plants can get higher quality fuel and with lower costs by using an optimized supply chain. This was the statement that was made in Ramboll Finland Oy’s report. Report was carried out in Cleantech Finland Bioenergy project, managed by Miktech Oy. Reviewed companies were Fixteri Oy (stem wood baler), MHG Systems (ERP), Saimatec Engineering Oy (biomass dryer) and Inray Oy (online fuel quality measurement system)

“Quality improvement, particularly moisture and homogeneity, has significant effect to the profitability of the power plants”, says business manager Mirja Mutikainen Ramboll Finland Oy.

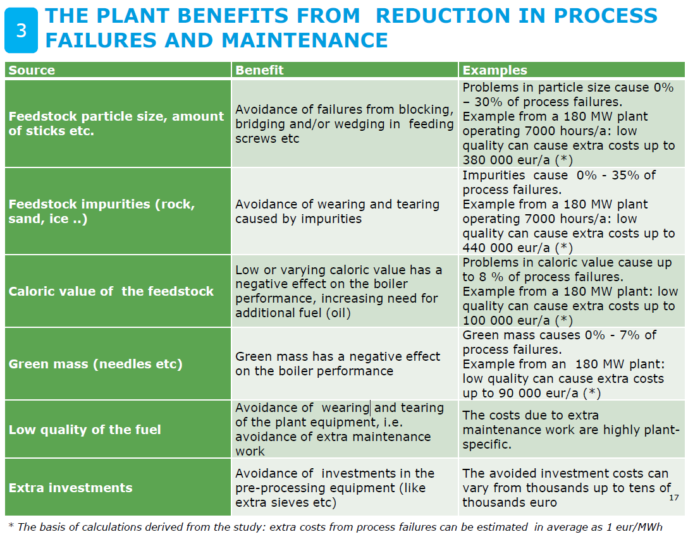

“The most concrete benefits are achieved in fuel economy, the boiler efficiency and in other energy production costs. The power plant’s benefits are also decreased production disturbances and savings in operational and maintenance costs.”

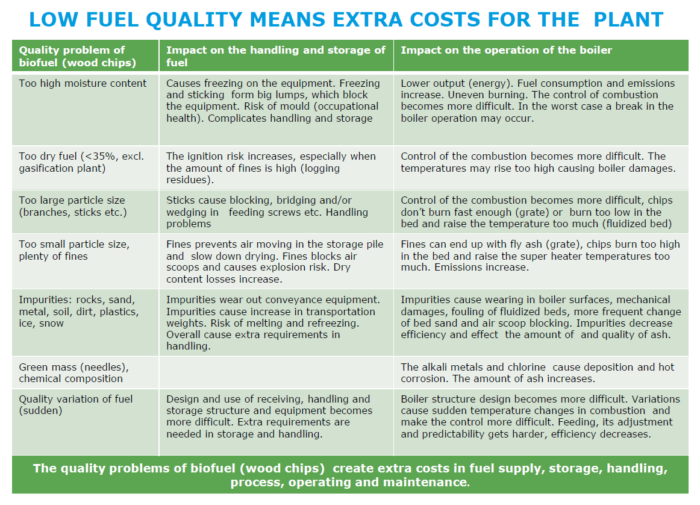

Solid biofuel’s moisture, wrong particle size, foreign matter, contaminants and green chips causes significant extra costs (Table 1). According to the report low fuel quality can cause over one million euros annual additional costs to 180 MWth biopower plant (Table 2). Inray Fuel online quality measurement system can be exploited to improve the fuel quality and reduce these extra costs. Online quality measurement enables also the optimization of the fuel mixes, and thus operate the power plant more efficiently.