At Inray, we’re revolutionizing biomass fuel management with our cutting-edge Fresh Wood Chip Detection and Reporting System. This innovative solution, integrated into our advanced camera systems, helps power plants optimize their operations, reduce risks, and maintain high performance.

Why Fresh Chips Matter

Fresh wood chips, or green chips, are derived from recently felled trees or forest residues. While their use has grown due to economic and supply pressures, these chips come with a hidden cost: their high chlorine and alkaloid content. These compounds can accelerate corrosion in boilers, leading to costly repairs and downtime.

Without systematic monitoring, power plants often operate blind, unaware of how much green wood they’re burning and the potential risks involved. That’s where Inray comes in.

The Problem with Green Chips

Fresh chips frequently contain green needles and leaves, which can drastically increase chlorine levels. This issue is especially prevalent in coastal regions, where trees absorb more chlorine. In the past, green chips were considered undesirable, even banned at some power plants.

But as the industry evolves, so do the challenges:

- Economic Pressure: Long storage times lead to dry matter losses, pushing suppliers toward faster inventory turnover.

- Fuel Shortages: When high-quality biofuels are limited, plants often have no choice but to burn what’s available—even if it includes green chips.

- Corrosion Risks: Without proper monitoring, a minor miscalculation in fuel mix can lead to boiler fouling and corrosion, causing operational disruptions.

The Inray Solution: Smarter Fuel Monitoring

Inray’s advanced camera and X-ray systems offer a game-changing approach to fuel management. Our system doesn’t just monitor—it empowers.

Key Features:

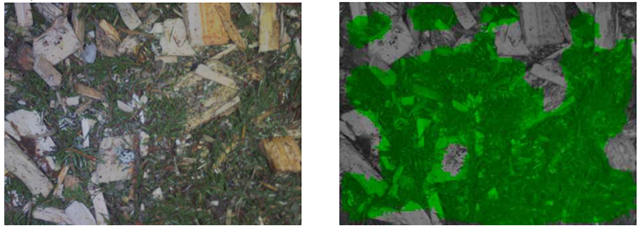

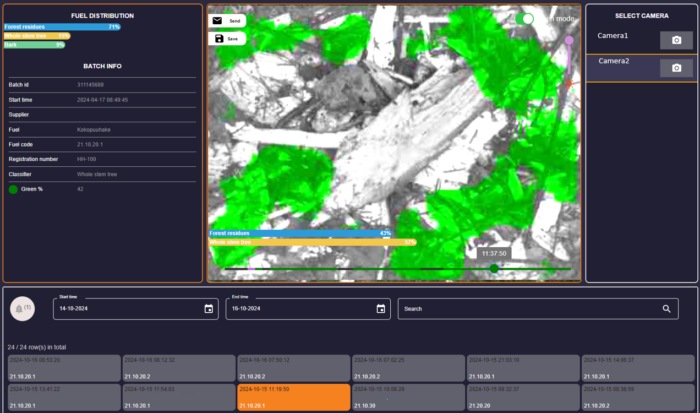

- Automated Green Chip Detection: Our image recognition software identifies green particles (like needles and leaves) in real-time.

- Data-Driven Insights: Each load is analyzed, and green chip content is quantified, providing actionable data to operators.

- Customizable Alerts and Reports: Operators can set threshold values and receive instant alerts when limits are exceeded. Plus, detailed reports offer a comprehensive view of fuel quality over time.

With our FUELCONTROL® Storage Silo Model, plants can track green chip content across storage silos in real-time. This ensures optimal fuel mixing and prevents harmful spikes in green chip usage.

Real-Time Benefits, Long-Term Value

Imagine knowing exactly what’s heading into your boiler hours before it gets there. With Inray, that’s now possible. Our system gives operators a complete picture of fuel composition, enabling smarter decisions and minimizing risks.

- Boost Efficiency: Reduce unplanned maintenance by preventing boiler corrosion.

- Enhance Coordination: Improve communication with fuel suppliers, ensuring better quality control.

- Stay Ahead of Issues: With real-time data, potential problems are identified and addressed before they escalate.

Proven Results, Trusted Technology

Inray has already delivered over 20 x-ray scanners and camera systems to power plants, helping them maintain continuous quality control. Our new green chip detection feature is the latest in a long line of innovations designed to keep your operations running smoothly.

See the System in Action

Real-Time Detection from every image:

Automatic reporting by supplier, fuel type and truck:

Real-time visualization of fuel distribution in silos:

Ready to Optimize Your Operations?

Take control of your fuel quality today. With Inray’s Fresh Wood Chip Detection System, you’ll gain the insights you need to run your plant more efficiently, reduce costs, and stay ahead of the competition.

Contact us now (contact@inray.fi, tel. +358 50 3509071) to learn how we can help transform your fuel management strategy.