In year 2015, Inray Fuel has scanned over one thousand truckloads of solid bio fuels. For the first time, there is such a big amount of fuel quality data available. After studying minute moisture data, it can be found out that the moisture deviation can be high even with homogenous fuels, which highlights the importance of total scanning.

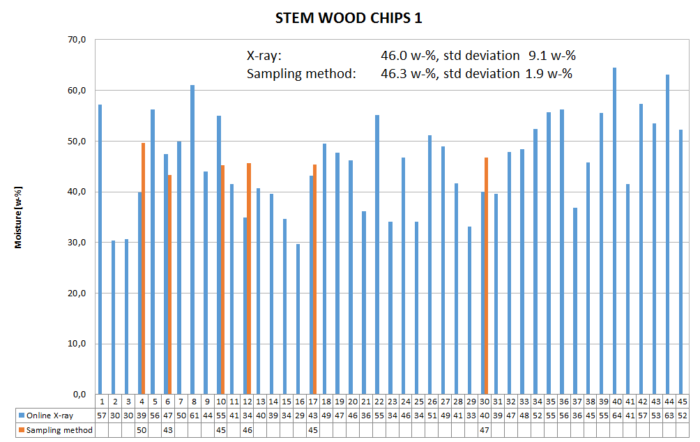

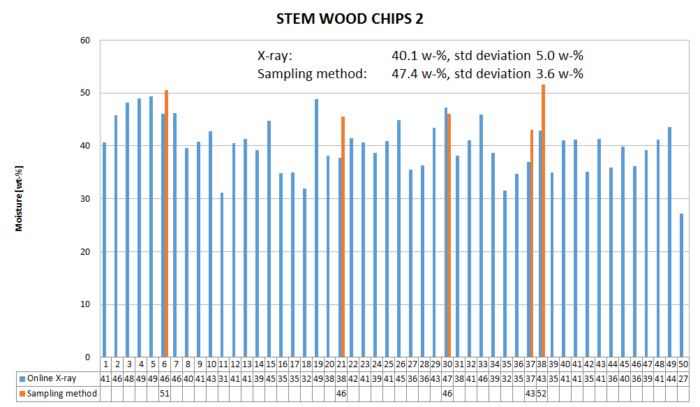

In the figure1, is shown the data of a stem wood chip batch, which should be homogenous fuel. Red beams refers to manual sampling results and blue ones to X-ray results. Volume of sample is normally 0.3% of fuel volume that is scanned in one minute. Results shows that person who took the samples was extremely skilled or lucky. In the figure2, the situation is opposite. The standard deviation was lower than in the first case one but he managed to take samples from the wet parts of the batch.

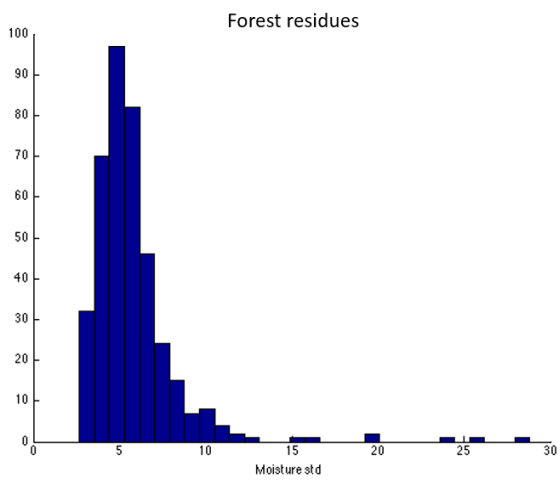

In many studies, it is often used average standard deviation for each fuel type to define the accuracy of sampling based method. In Finnish biofuel quality instructions (VTT-M-07608-13) this standard deviation for forest chips is 4.9 %. As seen in figure 3, this average value often gives a false impression since each truckload is individual. Standard deviation of one truckload can be anything between 2 to 20 %-points. Part of this big variation can be explained with varying storage time and conditions there. Also for logistic reasons one truck load of fuel can be from different storages. It has to be noticed that standard deviations for each truck in figure 3 are calculated from minute based data so there can be found more moisture variation within each minute. This is the challenge what normal sampling meets. Is the sample representing well enough this fuel or not?