The growing use of recycled raw materials demands reliable quality assurance to optimize and enhance production processes. This need arises from the scarcity of desired raw materials, the necessity to utilize increasingly lower-grade fractions, and the aim to use them in an energy- and cost-efficient manner. Quality parameters vary depending on the raw materials and production processes. Impurities degrade the quality of the final product, so it is essential to identify quality deviations early and remove them from the process if necessary.

One particularly serious issue is the presence of batteries and accumulators among recycled materials, which has led to major fires in raw material storage facilities across Europe. When material is handled and baled, an unnoticed battery may be damaged, start to heat up, and eventually cause a fire under the right conditions. Another significant hazard for production lines is large metal objects, which can break shredders or cause blockages.

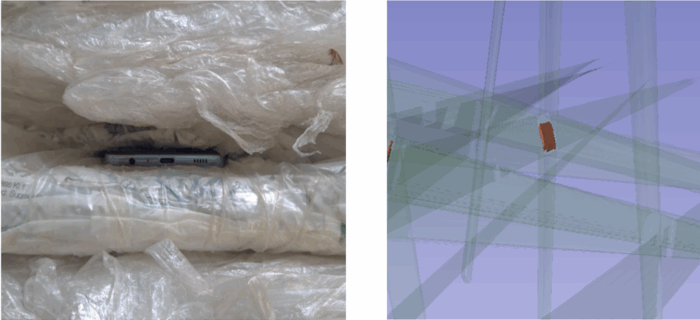

It is not always possible to verify the content of loose recycled material on a conveyor before baling. Post-baling quality control is relatively easy to implement, but by then it may be too late. To address this challenge, we have developed a scanning station capable of scanning even large items in multiple positions. In addition to X-ray scanning, the station is equipped with traditional camera technology that allows visual assessment of the bale’s contents and cleanliness. Below is an example of identifying an item inside a plastic bale.

The conveyor system with integrated scanning, built into a shipping container, can be relocated to a recycling facility when needed and put into operation quickly. Items to be scanned can be transferred into and out of the station using conveyors or roller tracks added to the front and rear of the container. If these are not available or suitable, items can be placed into the container using a forklift, after which the container's built-in conveyor and turntable manage the handling process.

Project name: Development of quality measurement station for recycled raw materials 902159

Implementation period: 2024-2025

Share of EU funding: 153,829 euros.